What is Technical Drawing? What is the necessity of Technical Drawing?

Technical drawing is basic for imparting thoughts in industry and engineering. To make the drawings more clear, individuals use familiar symbols, perspectives, units of measurement, notation systems, visual styles, and page design. Together, such conventions constitute a visual language and help to guarantee that the attraction is unambiguous and moderately straightforward.

A large number of the images and standards of Technical drawing are systematized in an international standard called ISO 128.

The requirement for exact correspondence in the arrangement of a practical record recognizes specialized drawing from the expressive drawing of the visual expressions.INSTRUMENTS USED IN TECHNICAL DRAWING OR ENGINEERING DRAWING

Attracting instruments are utilized to get ready drawings effectively and precisely. The exactness of the drawings relies to a great extent upon the nature of instruments. With instruments of great quality, attractive precision can be accomplished effortlessly, it is, hence, fundamental to acquire instruments of as unrivaled quality as could reasonably be expected.

The following is the rundown of the least drawing instruments and other drawing materials that each understudy must be familiar with :

1. Drawing Board.

2. T-square.

3. Drawing Sheets.

4. Drawing Sheet Container.

5. Drawing instrument box, containing:

(i) Large-size compass with inter-changeable pencil and pen legs.

(ii) Lengthening bar.

(iii) Bow compass or Small size compass.

(iv) Large-size divider.

(v) Bow divider or Small size divider.

(vi) Ruling pen or Ink pen.

(vii) Ruling pen attachments for compass.

(viii) Technical pen.

6. Scales.

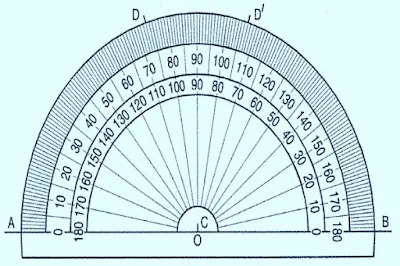

7. Protractor.

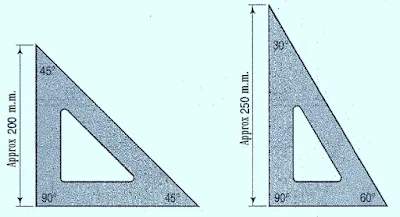

8. Set-squares, 45° and 30°- 60°.

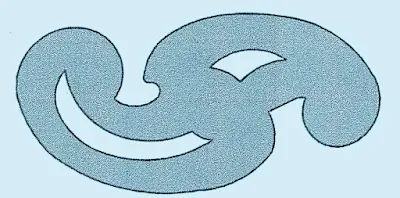

9. French curves.

10. Drawing pencils.

11. Pencil Lead case or Box.

12. Eraser (Rubber).

13. Erasing shield.

14. Sand-paper block or Pencil sharpener.

15. Drawing pins, clips, or adhesive tapes.

16. Duster.

17. Roll-n-draw.

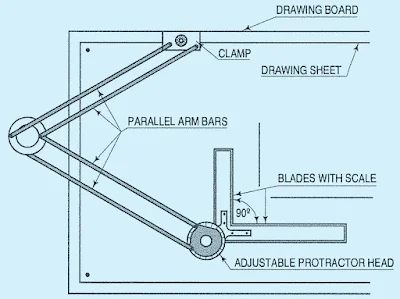

18. Drafting machine.

We shall now describe each of the above in detail with their uses :

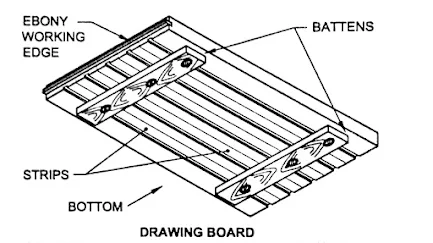

1. DRAWING BOARD

The drawing Board is rectangular fit as a fiddle and is made of stripes of all-around prepared delicate wood around 25 mm and 15 mm. thick. It is cleated at the back by two battens to forestall twisting.

One of the edges of the board is utilized as the working edge, on which the T-square is made to slide. It should, hence, be perfectly straight. In certain boards, this edge is grooved all through its length, and an entirely straight Ebony edge is fitted inside this depression. This gives a valid and tougher guide for the T-square to slide on.

SIZES OF DRAWING BOARDS ( B or D )

SIZES (Width × Length × Thick)

B0 or D0 1000×1500×25( mm.)

B1 or D1 700×1000×25( mm.)

B2 or D2 500×700×15 ( mm.)

B3 or D3 350×500×15 ( mm.)

The drawing board is made in different sizes. Its choice relies on the size of the attractive paper to be utilized. The extent of planning phases suggested by the Bureau of Indian Standards (IS:1444-1989) are arranged.

For use in schools and universities, the last two sizes of the drawing boards are more advantageous. Huge size sheets are utilized in drawing workplaces of designers and designing firms.

The drawing board is put on the table before the understudy, with its working edge on his left side. It is more helpful if the table-top is inclining downwards towards the understudy. If such a table isn't accessible, the vital slant can be acquired by putting an appropriate square of wood under the far-off longer edge of the board.

2. T-Square

T-Square is comprised of hard-quality wood, celluloid, or plastic. It comprises two sections named the stock or head and the blade - consolidated at right-angle(90°) to one another by methods for screws and pins. One of the distant edges of the blade which is generally beveled, is used as the working edge of T-square. The stock is set bordering the ebony edge of the board and is made to slide on it as and when required. The blade lies on the surface of the board.

The working edge should be completely straight. The nearer edge of the blade is rarely utilized.

The length of the blade is chosen to suit the size of the drawing board. The standard T-squares are as follows with dimensions shown in mm, as per IS:1360-1989.

SIZES OF T-SQUARES ( T )

SIZES ( Length of BLADE )

T0 1500 ( mm.)

T1 1000 ( mm.)

T2 700 ( mm.)

T3 500 ( mm.)

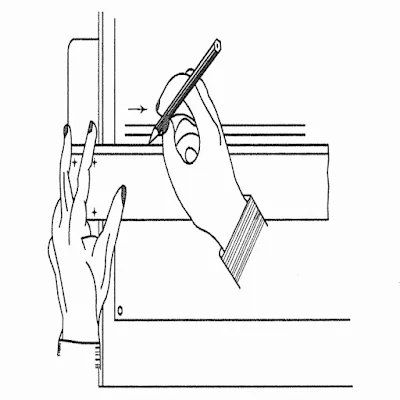

(i) The T-square is utilized for drawing horizontal lines. The stock or head of the T-square is held immovably or firmly with the left hand against the working edge of the board, furthermore, the line is drawn from left to right. The pencil ought to be held marginally slanted toward the direction of the line (for example to the right) while the pencil point ought to be as close as conceivable to the working edge of the blade. Horizontal parallel lines are drawn by sliding the stock to the required ideal positions.

ii) The working edge of the T-square is additionally utilized as a base for set squares to draw vertical, slanted, or commonly equal lines. A pencil must be pivoted while drawing lines for uniform wear of lead. T-square ought to never be utilized other than the ebony or working edge of the board. lt ought to consistently be kept on the board in any event, when not being used.

(iii) Testing the straightness of the working edge of the T-square: Mark any two points A and B divided wide separated and through them, cautiously draw a line with the working edge. Now, flip around the T-square as appeared by ran lines and with a similar edge, draw a different line going through the same two points. On the off chance that the edge is defective, the lines won't coincide.

The mistake ought to be corrected by planning or sand-papering the defective edge.

3. Drawing Sheets

Drawing sheets or papers are two types :

Hand-made sheets or papers :

Mill made sheets or papers :

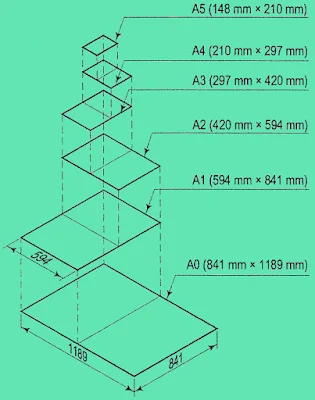

PAPER OR SHEET SIZES FROM 4A0 TO A10

4A0 1682 x 2378 (mm)

2A0 1189 x 1682 (mm)

A0 841 x 1189 (mm)

A1 594 x 841 (mm)

A2 420 x 594 (mm)

A3 297 x 420 (mm)

A4 210 x 297 (mm)

A5 148 x 210 (mm)

A6 105 x 148 (mm)

A7 74 x 105 (mm)

A8 52 x 74 (mm)

A9 37 x 52 (mm)

A10 26 x 37 (mm)

Paper sizes from 4A0 to A3, are generally used for drawing where 4A0 to A0 papers are used in industries and A1 to A4 papers are used in schools & colleges. The A4 size has become the standard business letter size. A5 to A10 papers are used for books, notebooks, pocket notebooks, etc.

4. Drawing Sheet Container

Drawing sheet containers are comprised of hardwood, and bamboo, or in modern days it's made with heavy-duty plastics. It's also termed as a Chart holder, Chart container, Draft tube, Drafting tube, Drawing tube, etc.

Drawing sheet containers, which are easily available in the market, are generally used for school and college students. It has an 8 c.m. internal diameter of the tube is 51 c.m. in length and extendable up to 80 c.m. or 31 inches. with a shoulder carrying strap which ensures extreme portability. It protects sheets from any external damage even from paper-worm bites and ensures a very long paper life.

5. Drawing Instrument Box

The following instruments should be in your instrument box. For keeping and carrying the drawing instruments safely, we can use a drawing instrument box, and you can buy this separately from the market. Thus there is no mandatory requirement to bring an instrument box except to keep your drawing instruments safer, but the drawing instruments are mostly required to start your drawing.

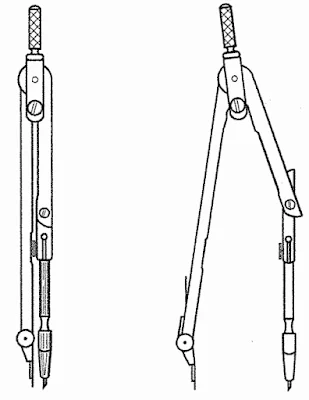

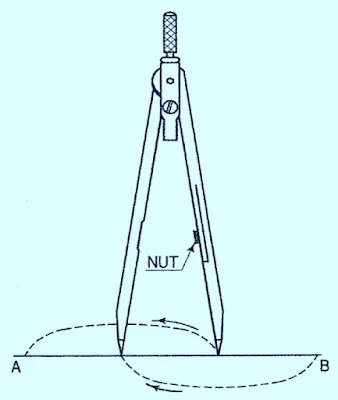

(i) Large-size engineering compass with inter-changeable pencil and pen legs :

The compass is utilized for drawing circles and arcs. It comprises two legs pivoted together at its upper end. A sharp needle is fitted at the lower end of one leg, while a pencil lead is embedded toward the finish of the other leg. The lower part of the pencil leg is separable and it tends to be exchanged with a comparable piece containing an inking pen. Both the legs are furnished with knee joints. Circles up to around 150 mm radius can be drawn with the legs of the compass kept straight. For drawing bigger circles, both the legs should be bowed at the knee joints so they are perpendicular to the surface of the paper.

As the needle needs to be embedded somewhat inside the paper, it is kept longer than the lead point. The setting of the pencil-lead is compared with the needle, and what's more, the shape to which the lead should be ground.

To draw a circle, adjust the opening of the legs of the compass to the required radius. Hold the compass with the thumb and the initial two fingers of the correct hand and spot the needlepoint gently in the middle, with the help of the left hand. Bring the pencil point down on the paper and swing the compass about the needle-leg with a spot of the thumb and the two fingers, in the clockwise direction, until the circle is finished. The compass ought to be kept marginally slanted toward the path of its revolution. while drawing concentric circles, starting ought to be made with the smallest circles.

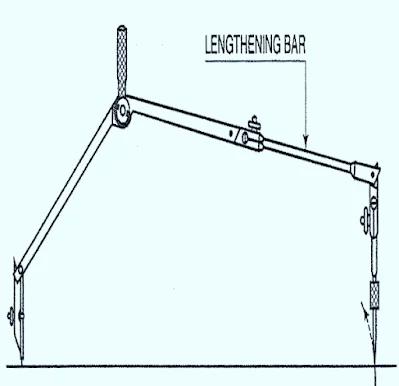

(ii) Lengthening bar :

In a large-size engineering compass,, the lower part of the pencil leg can be separated and the Lengthening Bar is embedded in its place. The Pencil leg is then fitted toward the finish of the lengthening bar, consequently expanding the length of the pencil leg.

It is regularly important to control the pencil leg with the other hand while drawing enormous circles. Circles with more than 150 mm radius are drawn with the help of the lengthening bar, mostly used in industrial drawing.

(iii) Bow compass :

For drawing little circles and curves of under 25 mm radius and especially, when countless little circles of the equivalent diameter need to be drawn, a small bow compass is utilized. This type of compass is smaller in size than ordinary compasses so sometimes it is termed a small-size compass.

(iv) Large-size divider :

The divider has two legs pivoted at the upper end and is given steel pins at both the legs on the lower ends, yet it doesn't have knee joints.

The dividers are utilized for :

(i) It is used to divide straight or curved lines into a desired number of equal parts.

(ii) This can be used to transfer measurements from one part or portion to another part or portion of the drawing.

(iii) It is used to set off given dimensions from the scale to the drawing.

Large dividers are extremely advantageous for setting off points at equal distances along a given line.

(v) Bow divider :

The bow divider is smaller in size than ordinary dividers, for this reason sometimes it's termed as a small divider. The bow divider is adjusted by a wheel nut and a spring. It is very helpful for marking very small divisions. It is also very convenient for a huge number of short equivalent separations.

(vi) Ruling pen or ink-pen :

The Ruling pen is a technical or engineering drawing instrument for drawing with ink or with other drawing fluids. This is utilized for drawing straight lines and non-circular arcs. It comprises a pair of steel nibs or jaws that are tapered to meet at a point and are approximately 11.8 c.m in length. It's very useful to draw very thin lines. The line width can be adjusted by an adjustment screw connecting the jaws. fitted to a holder made of metal or ivory. Ink is filled between the two nibs to about 6 mm internal diameter of a quill which is usually fitted with the cork or rubber. The ink flow line between the nibs through which the ink flows and upon which the thickness of the line depends is adjusted using the screw that optionally has an ink flow intensity controlling number dial.

The pen ought to be continued inclining at about 60° with the paper toward the direction of drawing and the finishes of the nibs ought to be marginally away from the edge of the T-square or set-square or scale.

(vii) Ruling pen attachment for compass :

Ruling pen attachments or Inking pen attachments are utilized for drawing circles and circular arcs, these ought to be fitted instead of the pencil leg in the compass.

In the Ruling pen attachments, drawing ink or other drawing fluid dries rapidly, for this reason, the Ruling pen should be used immediately after it is filled with ink. The inside faces of the nibs should be frequently wiped out with a cleaned soft cotton cloth for the freely flowing ink and to maintain the uniform thickness of lines.

(viii) Technical pen :

Technical pens are also very useful instruments used for engineering drawing, especially for electrical engineering drawing where various color indicators are also needed to draw for indication. However, it's frequently used in all types of engineering drawing industry.

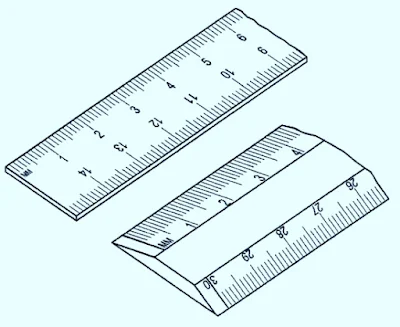

6. Scales

It is an instrument by which the length of an object or the shortest distance between two points can be measured. So, a scale is a length-measuring instrument. It is also used to transfer the true or relative dimensions of an object in the drawing.

There are generally five types of scale but three types of scale have huge applications or are mainly used in engineering graphics, those are :

(i) Plain Scale,

(ii) Diagonal Scale and

(iii) Vernier Scale.

(Apart from the above, Comparative Scale & Scale of Chords are also classified as types of scale.)

In engineering drawing or technical drawing, Plain scale and Diagonal scale are mainly required and both types of scale also have a huge application in drawing. Vernier scale is mainly used in technical or engineering workshops.

Scales are made of wood, steel, celluloid, plastic, or cardboard. 15 cm long and 2 cm wide or 30 cm long and 3 cm wide level scales are in Common use. They are ordinarily around 1 mm thick. However, a 15 c.m. long and 2 c.m. wide scale is considered as the Standard length of the scale.

Least count of Plain scale = 0.5 mm.

Least count of the Diagonal scale = 0.01 mm.

Least count of Vernier scale = 0.02 mm.

[ N.B. Least count is a minimum distance or length that can be measured by a scale. ]

The scale should not be used as a straight edge for drawing lines to avoid the wear or damage of the edges.

For details about SCALE, you can learn it from here!

7. Protractor

A protractor is an angle-measuring instrument used in technical drawing or engineering drawing. It is made of wood, tin, plastic, fiber, or celluloid. Nowadays, Protractors of transparent celluloid are common in use. Protractors are circular-flat or semi-circular-flat in shape. The commonest type of protractor is semi-circular and it's about 100 m.m. diameter. lts Circumferential edge is graduated with 1°divisions upto 180°, is numbered at every 10° interval. The diameter of the semi-circle (viz. straight line 0-180°) is called the base of the protractor and its center 'O' Is marked by a line perpendicular or 90° to it.

The protractor is used to draw or measure such angles which cannot be drawn with set-squares. A circle can be divided into any number of equal parts using a protractor.

8. Set-square

As per IS:1361-1988, the set-squares were made of wood or tin, etc. but nowadays, Set-squares are made of transparent celluloid or plastic as they retain their shape and accuracy for a very long time. There are two forms of set-squares for general use in engineering drawing. One is called 45° Set-square and another is termed as 30°-60° Set-square. A set-square is a flat triangular shape with one of its angles at a right angle(90°). Set squares may have smaller or larger sizes. Smaller size set squares can be found in the geometry box. A large size set-square is used for engineering drawing. larger 30°-60° set-square has a base of 145 mm ( approx 150 mm. ) and height of 245 mm ( approx 250 mm. ) whereas a 45° set-square has a base and height of 195 mm ( approx 200 mm ).

(i) Set-squares are used for drawing all parallel straight lines except the horizontal lines which are usually drawn with the T-square more easily. Vertical lines can be drawn with the T-square and the set-square. However, horizontal lines, vertical lines, and parallel lines are also can be drawn with a set square by an expert hand (Not recommended for beginners) and it can omit the use of T-square.

(ii) Parallel straight lines in any position, not very far apart, as well as lines perpendicular to any line from any given point within or outside it, can also be drawn with the two set squares.

(iii) A circle can be divided into six, eight, twelve, and twenty-four equal parts by using set squares.

(iv) Lines at 30° or 60° angle with vertical or horizontal lines can be drawn with 30°- 60° set-square and 45° angle with 45° set-square. The two set-squares, used simultaneously, can produce angles of 15, 75°, 105° etc.

9. French curves

10. Drawing Pencils

The quality of a drawing is highly dependent on the grade selection of the pencils used. With the wrong grade selection of pencils, it is very difficult to draw lines with uniform shade and proper thickness.

The grade of a pencil lead is usually shown by digits and letters marked at one of its ends. Letters HB ( Hard & Bold ) denotes the Medium grade. The increase in hardness is more useful to draw faint or thin-light lines and it is denoted by the value of the digit put in front of the letter H ('H' indicates Hard), viz. 2H, 3H, 4H etc. Similarly, the grade becomes softer according to the digit placed in front of the letter B ('B' indicates Bold), viz. 2B, 3B, 4B etc. A softer pencil is used to draw dark & thick lines.

For beginners, drawing should be made with HB or 2H pencil, so that the lines are faint, and unnecessary or extra lines can be easily erased. The final fair work may be done with softer pencils, i.e. 2B and upwards.

H and HB pencils are more suitable for dimensioning. For freehand sketching where considerable erasing is required to be done, medium-grade pencils such as HB should be used.

11. Pencil Lead Case or Box

A pencil lead case or pencil lead box is used to keep pencil leads safe and it protects leads from breakage or any damage as pencil leads are made with soft polymer or graphite.

12. Eraser (Rubber)

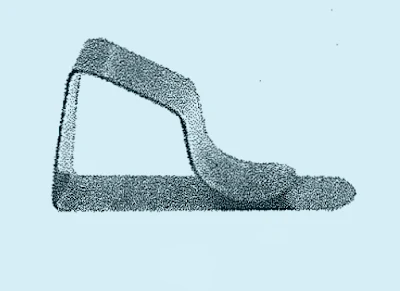

13. Erasing shield

|

| Erasing Shield in Use |

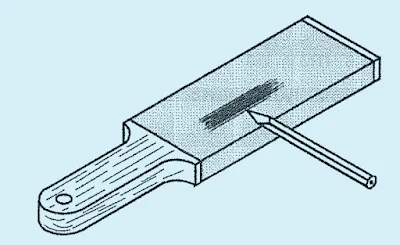

14. Sand-paper block or Pencil sharpener

|

| Sand Block |

|

| Pencil Sharpener Machine |

15. Drawing pins, clips, or adhesive tapes

|

| Board Clips |

|

| Board Pins |